OPERATIONAL MANUAL FOR 20” STEEL SCAFFOLD BRACKETS SOLD BY CORRIVEAU CONCRETE FORMING SUPPLIES LTD.

CAUTION: READ AND FOLLOW OPERATING INSTRUCTIONS. THIS IS ONLY A GUIDE AS CONSTRUCTION SITES VARY GREATLY AND WE CAN NOT BE RESPONSIBLE FOR HOW THIS PRODUCT IS USED. USE PRODUCT AT YOUR OWN DISCRETION. FAILURE TO DO SO CAN RESULT IN SERIOUS INJURY OR EVEN DEATH. PLEASE CHECK WITH YOUR HEALTH AND SAFETY OFFICER AND THE MOST RESENT OCCUPATIONAL HEALTH AND SAFETY ACT AND REGULATIONS FOR CONSTRUCTION PROJECTS FOR ANY ADDITIONAL HEALTH AND SAFETY PROCEDURES THEY MAY BE IN PLACE.

INSTRUCTIONS:

· Scaffold brackets should be checked before and during use for any defects. Defects should be noted and repaired by a qualified person before scaffold bracket is used. If damages are beyond repair the scaffold bracket should be taken OUT OF SERVICE, recycled (where recycling facilities exist) and replaced.

· Only those people deemed competent should work with or near this product.

· Stay alert. Do not use this product when you are tired, ill, upset, or under the influence of drugs, alcohol or medication.

· DO NOT alter this product in any way.

· The maximum distance between any two brackets should not exceed 2.1 metres

· The maximum load per bracket should not exceed 2.4 kilonewtons per square metre

· Please refer to OHSA and Regulations for Construction projects for information about planks

Occupational Health and Safety Act and Regulations for Construction Projects states:

Access at Heights

125. (1) Where work cannot be done on or from the ground or from a building or other permanent structure without hazard to workers, a worker shall be provided with a scaffold, a suspended work platform, a boatswain’s chair or a multi-point suspended work platform that meets the requirements of this Regulation. O. Reg. 242/16, s. 9.

(2) A worker who is on or under a scaffold, a suspended work platform system or a multi-point suspended work platform while it is being erected, altered or dismantled shall be on a part of the scaffold, suspended work platform system or multi-point suspended work platform that meets the requirements of this Regulation. O. Reg. 242/16, s. 9.

126. (1) Every scaffold shall be designed and constructed to support or resist,

(a) two times the maximum load or force to which it is likely to be subjected, without exceeding the allowable unit stresses for the materials of which it is made; and

(b) four times the maximum load or force to which it is likely to be subjected without overturning. O. Reg. 213/91, s. 126 (1).

(2) Despite clause (1) (a), a scaffold with structural components whose capacity can only be determined by testing shall be designed and constructed to support or resist three times the maximum load or force to which it is likely to be subjected without causing the failure of any component. O. Reg. 213/91, s. 126 (2).

(3) No scaffold shall be loaded in excess of the load that it is designed and constructed to bear. O. Reg. 213/91, s. 126 (3).

127. (1) The failure load of a scaffold which consists of structural components whose capacity cannot be determined by testing shall be established by testing the components in a manner that simulates the actual loading conditions for which each of the components is fabricated. O. Reg. 213/91, s. 127 (1).

(2) A professional engineer shall verify and certify the results of a test and the corresponding rated load of the scaffold. O. Reg. 213/91, s. 127 (2).

(3) The constructor shall make available to an inspector upon request a copy of the certification by the professional engineer. O. Reg. 213/91, s. 127 (3).

128. (1) Every scaffold,

(a) shall have uprights braced diagonally in the horizontal and vertical planes to prevent lateral movement;

(b) shall have horizontal members that are adequately secured to prevent lateral movement and that do not have splices between the points of support;

(c) shall have footings, sills or supports that are sound, rigid and capable of supporting at least two times the maximum load to which the scaffold may be subjected without settlement or deformation that may affect the stability of the scaffold;

(d) shall have all fittings and gear, including base plates or wheels, installed in accordance with the manufacturer’s instructions;

(e) shall have connecting devices between frames that provide positive engagement in tension and compression;

(f) shall have safety catches on all hooks; and

(g) shall be adequately secured at vertical intervals not exceeding three times the least lateral dimension of the scaffold, measured at the base, to prevent lateral movement. O. Reg. 213/91, s. 128 (1).

(2) A scaffold shall be constructed of suitable structural materials and, if lumber is used, it shall be construction grade or Number 1 Grade spruce. O. Reg. 213/91, s. 128 (2).

131. Only a competent worker shall supervise the erection, alteration and dismantling of a scaffold. O. Reg. 213/91, s. 131.

134. (1) Every scaffold platform and other work platform shall be designed, constructed and maintained to support or resist, without exceeding the allowable unit stresses for the materials of which it is constructed,

(a) all loads and forces to which it is likely to be subjected; and

(b) at least 2.4 kilonewtons per square metre. O. Reg. 213/91, s. 134 (1).

(2) Each component of a scaffold platform or other work platform shall be capable of supporting a load of at least 2.2 kilonewtons without exceeding the allowable unit stress for each material used. O. Reg. 213/91, s. 134 (2).

(3) No scaffold platform or other work platform shall be loaded in excess of the load that it is designed and constructed to bear. O. Reg. 213/91, s. 134 (3).

135. (1) A scaffold platform or other work platform,

(a) shall be at least 460 millimetres wide;

(b) if it is 2.4 metres or more above a floor, roof or other surface, consist of planks laid tightly side by side for the full width of the scaffold;

(c) shall be provided with a guardrail as required by section 26.3;

(d) shall be provided with a means of access as required by section 70;

(e) shall not have any unguarded openings; and

(f) shall have each component secured against slipping from its supports. O. Reg. 213/91, s. 135 (1); O. Reg. 527/00, s. 4.

(2) A scaffold platform or other work platform made of sawn lumber planks shall have planks of number 1 grade spruce that do not have any defect affecting their load-carrying capacity and,

(a) that bear a legible grade identification stamp or are permanently identified as being number 1 grade spruce;

(b) that are at least forty-eight millimetres thick by 248 millimetres wide;

(c) that are arranged so that their span does not exceed 2.1 metres;

(d) that overhang their supports by not less than 150 millimetres and not more than 300 millimetres; and

(e) that are cleated or otherwise secured against slipping. O. Reg. 213/91, s. 135 (2).

*PLEASE MAKE SURE TO ALWAYS CONSULT WITH THE MOST RECENT OCCUPATIONAL HEALTH AND SAFETY ACT AND REGULATIONS FOR CONSTRUCTIONS PROJECTS AS REGULATIONS CAN CHANGE*

REFERENCE: OCCUPATIONAL HEALTH AND SAFETY ACT AND REGULATIONS FOR CONSTRUCTION PROJECTS 2017

PLEASE CONTACT OFFICE FOR DRAWINGS

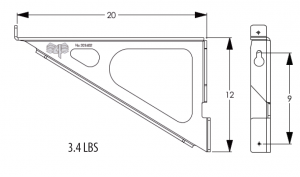

20" Aluminum Scaffold Bracket - Can be used on any panel. The top is attached to a bolt on the panel and the bottom is secured with a nail into the panel. This scaffold bracket is also available with a 2" x 2" pocket or a 2" x 4" pocket to install a guard rail for working at heights.

20" Aluminum Scaffold Bracket - Can be used on any panel. The top is attached to a bolt on the panel and the bottom is secured with a nail into the panel. This scaffold bracket is also available with a 2" x 2" pocket or a 2" x 4" pocket to install a guard rail for working at heights. The aluminum safety railing post can be made to fit a 2" x 2" pocket or a 2" x 4" pocket. Simply place the railing into the appropriate scaffold bracket and then insert the 2" x 4" pieces of lumber. **Please note the bracket is sold separately - picture shows a 20" aluminum bracket with a 2" pocket.**

The aluminum safety railing post can be made to fit a 2" x 2" pocket or a 2" x 4" pocket. Simply place the railing into the appropriate scaffold bracket and then insert the 2" x 4" pieces of lumber. **Please note the bracket is sold separately - picture shows a 20" aluminum bracket with a 2" pocket.**